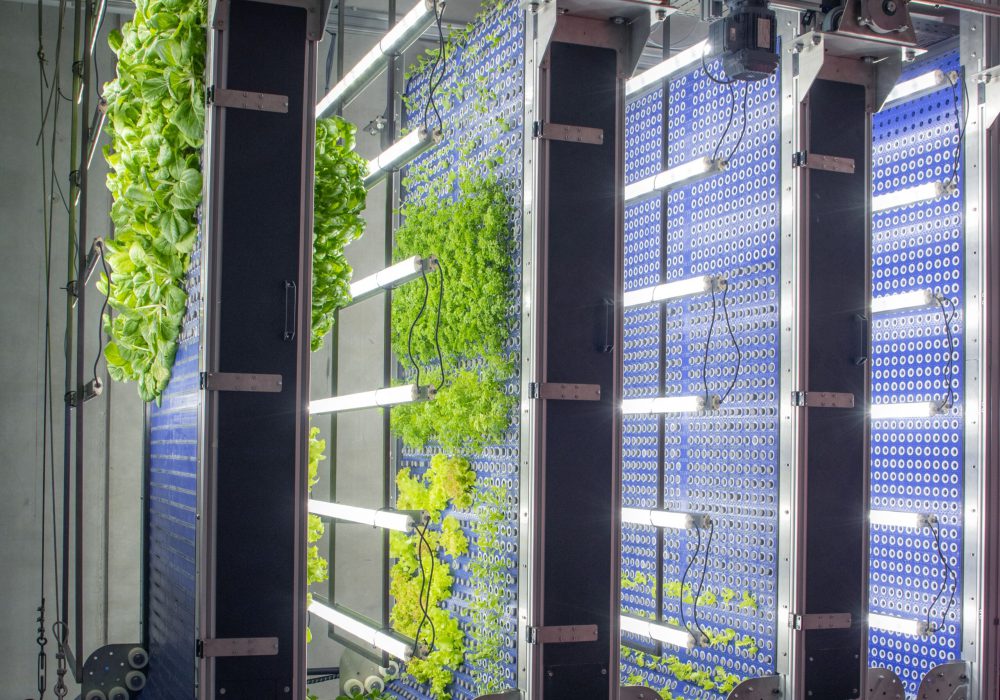

Your system partner for innovative automation solutions in plant engineering

Meissner is your experienced partner for automation technology and plant engineering—from the initial idea to series production. With over 100 years of experience in tool and mold making, we offer tailor-made automation solutions for industry. Our portfolio ranges from handling and processing systems to robot cells and customized special solutions for a wide variety of industries, including

blow molding manufacturing,

aluminum foundry tools, medical technology, toolmaking, and

additive manufacturing.

Our teams of electronics engineers, mechatronics engineers, and hydraulics and pneumatics experts develop innovative solutions that make your production processes more efficient, safer, and more sustainable. Whether it's prototype construction for foundries, tool repair and maintenance, or manufacturer-independent tool service – we rely on state-of-the-art technologies and the highest quality standards.

Functionality and precision

Our systems and solutions in plant engineering, automation technology, and toolmaking impress with their outstanding functionality, precision, and reliability. Thanks to innovative technologies, durable components, and modern quality management, Meissner tools ensure the highest possible added value in our customers’ production—from additive manufacturing and blow mold production to toolmaking services for aluminum and iron foundries.

The experienced Meissner team of experts develops tailor-made automation solutions for industry – whether standard systems, individual devices, or complex special solutions. Benefit from our expertise in tool repair and maintenance, manufacturer-independent tool service, and sustainable manufacturing solutions for your production.

Equipment and devices

- Palletizing and stacking systems Automated systems for efficient stacking and palletizing of products.

- Dry ice cleaning systems Innovative systems for gentle and effective cleaning of surfaces using dry ice.

- Post-cooling devices Special devices for controlled cooling of workpieces after the production process.

- Cooling tanks (single and double stations) Systems for cooling products at various stages of production.

- Heating stations For example, floor heating stations for melting or preheating components.

- Blank punching machines Precise punching systems for specific applications.

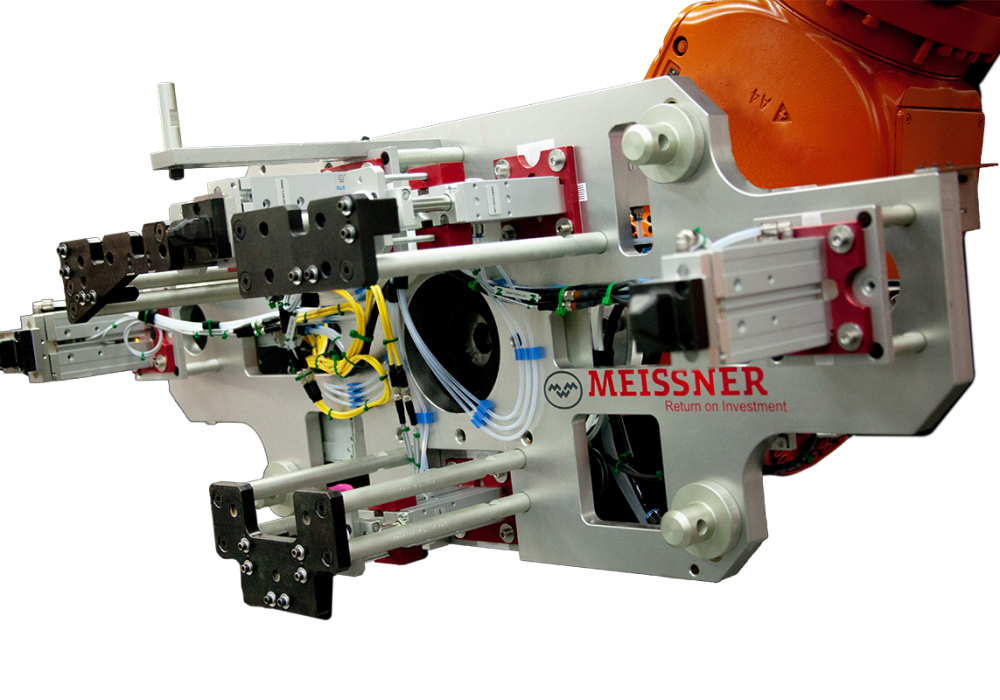

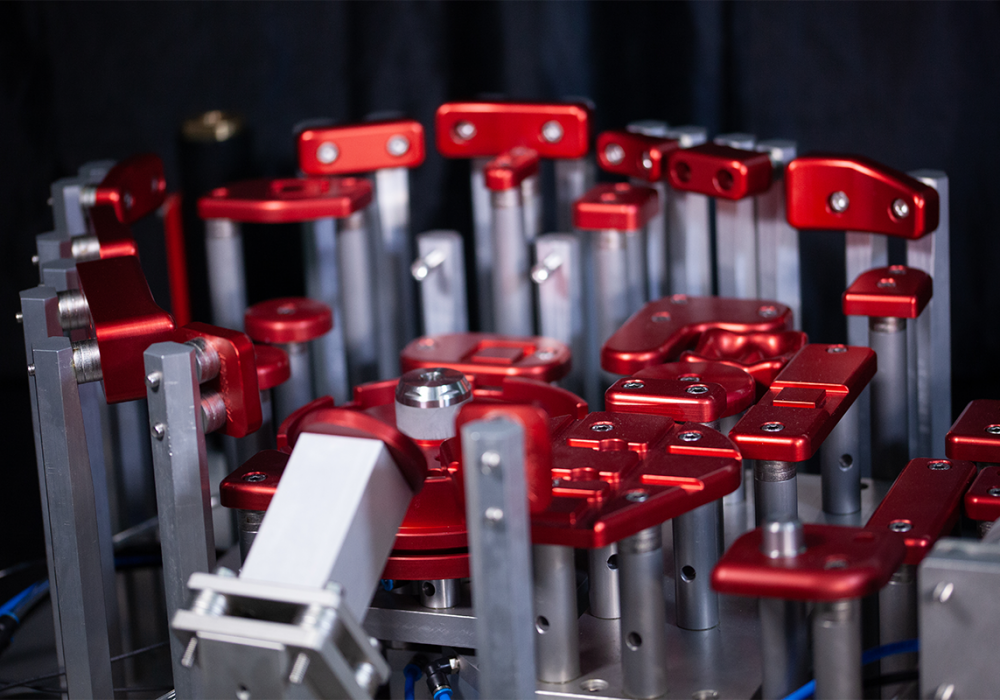

Automation technology

- Basements Foundations and base frames for machines and systems.

- Robotic grippers Specialized gripping systems for robotic applications.

- Handling devices Devices for the efficient handling of workpieces and materials.

- End-of-arm tools Tools for robot end effectors to perform specific tasks.

- Removal grippers Systems for removing workpieces from machines or production lines.

- Insertion devices for components Devices for the precise insertion of components into the production process.

- Handling tools for trimmings Special tools for handling and processing trimming materials.

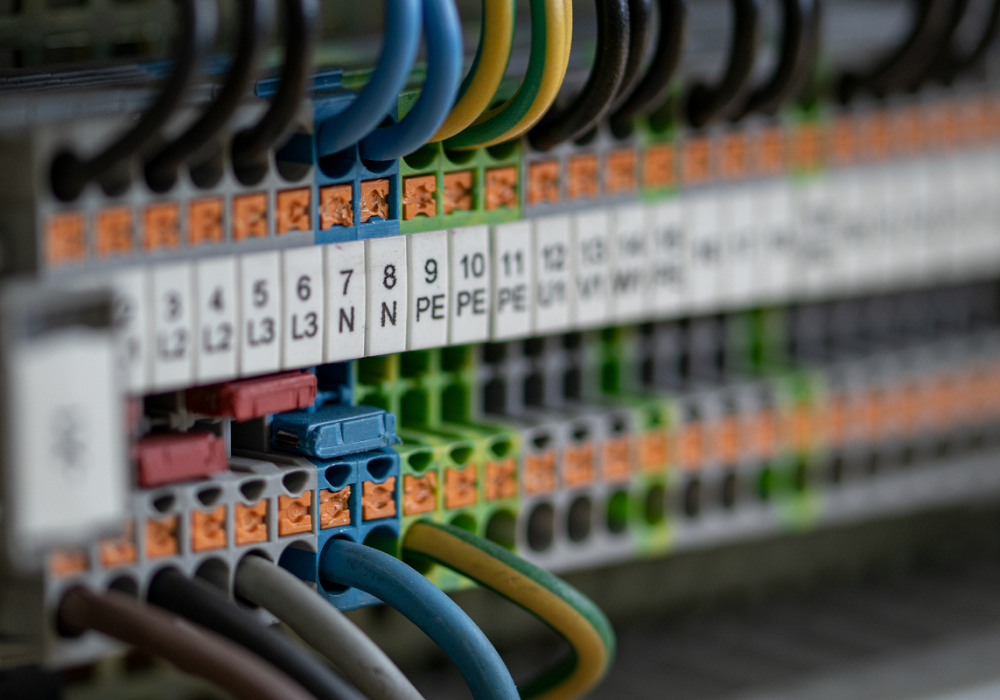

Planning and control

- Electrical and fluid plans Creation of electrical and fluid plans for systems.

- Robot programming Programming of industrial robots for specific applications.

- Process and program planning Planning and optimization of process flows and control programs.

Quality improvement

- Testing of mold functions using production-oriented flowcharts with PLC S7 Ensuring the functionality of molds and tools through simulation-based testing procedures.

- Control Targeted monitoring and control of production processes using automated and precise control systems.

- Endurance tests Long-term tests to check the stability and reliability of systems.

- Robot acceptance tests Acceptance tests of robot systems to ensure the required performance parameters.

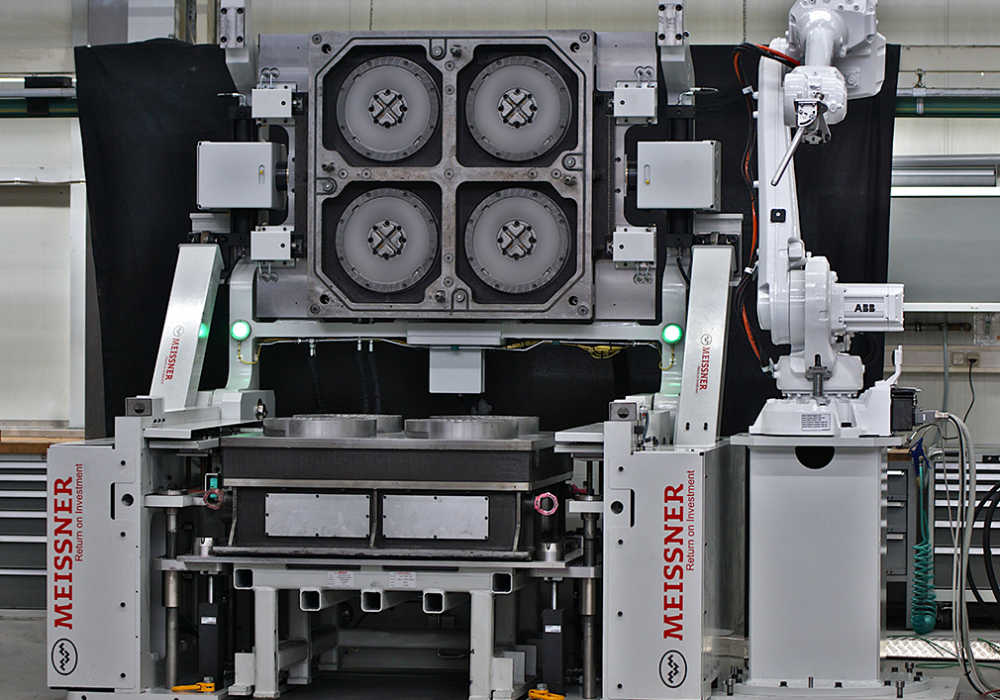

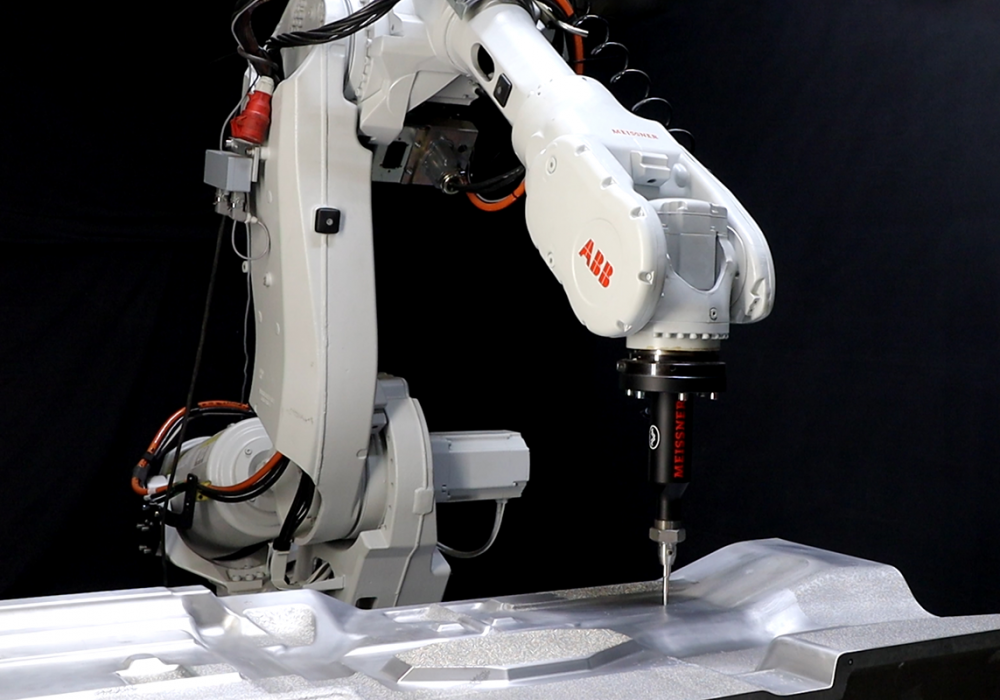

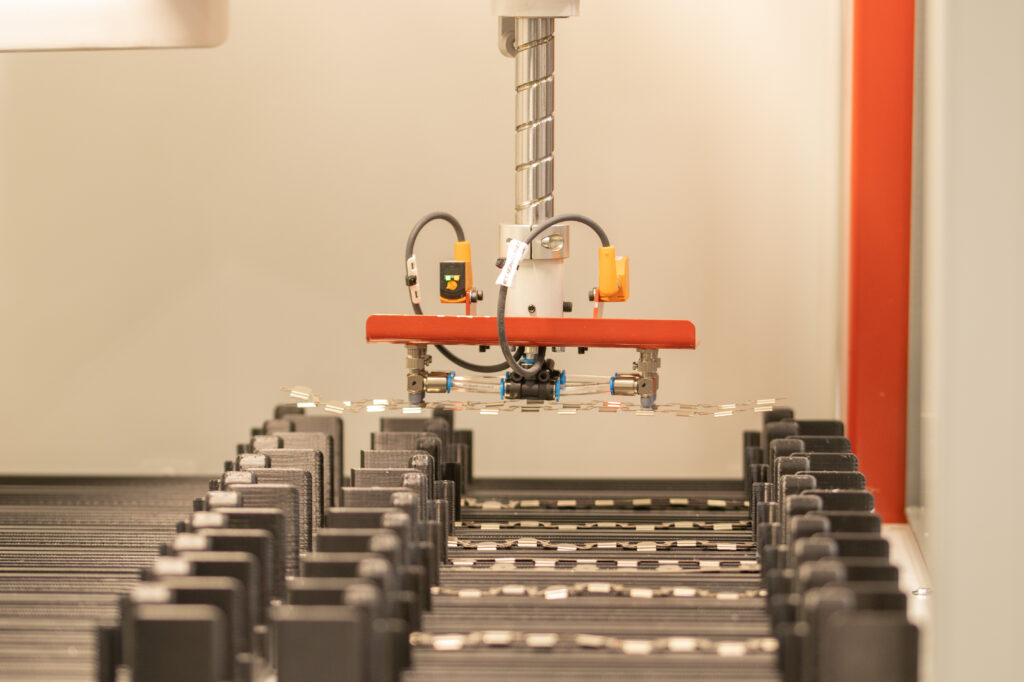

Pick-and-place: Automated handling at the highest level

With our sophisticated and specialized pick-and-place systems, Meissner offers you state-of-the-art solutions for the precise and efficient handling of components in your production. Our systems are individually tailored to your requirements and ensure maximum process reliability, speed, and repeatability—regardless of whether you are handling small parts or complex assemblies.

To give you a better insight into the diverse functions of our pick-and-place solutions, we would like to present three of these systems here:

Home storage organization - Automated handling for maximum productivity

With its innovative robot cell for sheet metal strips used in home storage systems, Meissner offers a future-oriented automation solution for modern manufacturing. The system precisely removes, stacks, and sorts sheet metal strips used in home storage systems, thereby significantly increasing efficiency, process reliability, and quality. The specially developed robot removes the finished sheet metal strips directly from the machine and sorts them fully automatically into stacks of 10 in the designated holders within the robot cell. This automated stacking replaces the previous manual activity and thus relieves your staff, who can now concentrate on value-adding tasks.

Your advantages at a glance

- Increased efficiency: Automated removal and stacking saves time, reduces sources of error, and increases production throughput.

- Process reliability: Consistent quality and precision when sorting and stacking sheet metal strips.

- Reduced workload for employees: The robot takes over monotonous and physically demanding tasks, thereby improving working conditions.

- Flexibility: The robot cell can be individually adapted to different

sheet metal strip formats and production requirements. - Seamless integration: The solution can be easily integrated into existing manufacturing processes and supports efficient further processing, e.g., during packaging.

Technical highlights

- Precise industrial robot for automated handling

- Intelligent control system for reliable sorting into stacks of 10

- Robust holders for secure temporary storage of sheet metal strips

- Ergonomic removal options for the packaging process

Rely on Meissner’s automation expertise and optimize your production of sheet metal strips for home storage—for greater efficiency, quality, and competitiveness. Contact us now for a personalized consultation and learn how you can sustainably improve your production processes with state-of-the-art automation technology.

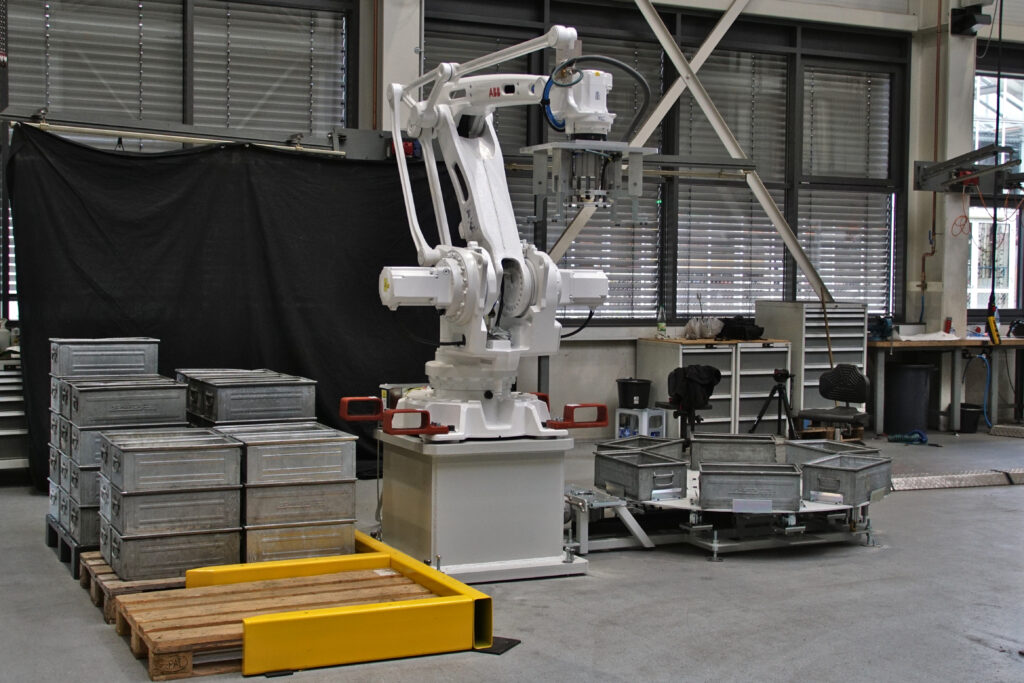

Stacking system – Automated palletizing for your production

The Meissner stacking system is an innovative and efficient solution for the automatic stacking and handling of crates in industrial manufacturing processes. It was specially developed to optimize material flow in production lines, reduce manual labor, and sustainably increase process reliability. Equipped with a precise turntable, powerful industrial robot, and intelligent pallet centering, the stacking system performs all palletizing steps fully automatically. Crates are reliably picked up, transported, shaken, and stacked precisely on up to three pallets. Smart sensor technology continuously monitors all processes. Thanks to its flexible configuration, the system is suitable for different crate sizes and pallet layouts. A closed protective enclosure and intuitive operation ensure maximum safety and easy handling.

Your advantages at a glance:

- Automated palletizing: Robots stack boxes quickly and precisely on up to three pallets.

- Efficient workflow: The turntable automatically transports, shakes, and positions the boxes for optimal filling and stacking.

- Safe & flexible: Closed protective housing, intelligent sensor technology, and simple operation guarantee maximum work safety and flexibility.

- Time-saving: Up to 40 boxes per cycle are stacked fully automatically – ideal for high quantities and continuous production.

Technical highlights:

- Robot with intelligent gripper for precise handling of boxes

- Turntable with sensors for exact positioning and efficient material flow

- Automatic fill level control and integrated shaking station to prevent parts from accumulating

- Easy operation via an intuitive control panel

With the stacking system from Meissner, you benefit from a continuous, automated workflow that increases your productivity, minimizes sources of error, and reduces the workload on your employees. Rely on state-of-the-art automation technology and take your production to the next level now—for greater efficiency, safety, and cost-effectiveness in your company.

Resistance testing system – Automated quality control and efficient handling

The resistance testing system from Meissner perfectly complements your stamping production and ensures automated quality control and efficient material handling. It fills, tests, and stacks boxes with stamped parts and can be seamlessly integrated into existing production lines. Thanks to modern automation technology and precise sensor technology, each stamped part is reliably tested during the filling process. A 4-axis robot sorts the parts precisely, while the “Resistomat 2304” testing device continuously ensures consistently high quality. This ensures maximum process reliability and product quality.

Your advantages at a glance:

- Automated resistance testing: During the filling process, stamped parts are continuously tested for electrical resistance using the customer’s “Resistomat 2304” testing device.

- Efficient material handling: A 4-axis robot handles the stamped parts and boxes with precision. A feed conveyor belt transports the parts from the stamping machine directly into the boxes, which are then automatically stacked.

- Integrated weighing device: The system determines the exact number of parts in each box, ensuring consistently high process accuracy.

- High capacity: The box stacker processes two stacks of up to eight boxes each, ensuring uninterrupted operation even with large quantities.

- Optimized removal: The roller conveyor belt transports the fully loaded boxes reliably and ergonomically to the collection position.

Technical highlights:

- 4-axis robot for flexible and precise handling

- Feed conveyor belt for automatic parts feeding

- High-capacity box stacker for efficient storage

- Roller conveyor belt for fast removal

- Integrated weighing technology for accurate part counting

With its high capacity and flexible configurability, the resistance testing system is ideal for demanding production environments. It relieves your staff of monotonous and physically demanding tasks and enables efficient, economical, and safe production—around the clock. Trust in Meissner’s experience and innovative strength and optimize your production processes now with an automated solution that takes quality and efficiency to a new level.

Numerous satisfied customers speak for themselves—our references

They offer you comprehensive insight into the diversity and range of successfully completed projects.