Your partner for additive manufacturing

The special feature: build size and feed rate

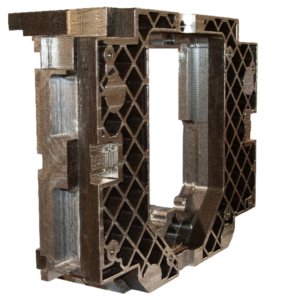

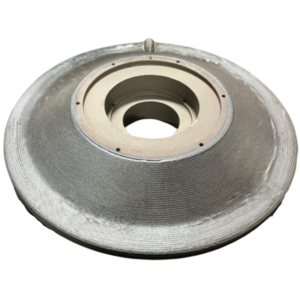

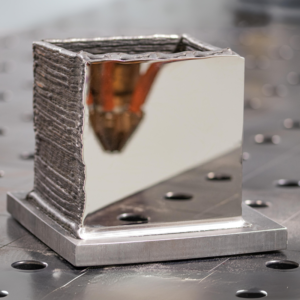

Our specially developed metal 3D printing system enables the production of larger components (up to approx. 1,200 mm x 2,000 mm x 1,000 mm) and works efficiently, with a processing speed of up to 7 kg of material per hour. This resource-saving process offers a cost-efficient alternative, especially for highly stressed components.

Material combinations that were previously thought impossible are also feasible – regardless of whether cast material needs to be protected against corrosion with stainless steel or a layer is applied as wear protection.

From the design to the finished component

Meissner AG’s metal 3D printing not only enables the generation of new components, but also the coating and repair of worn parts. Our close customer support for 3D printing projects enables rapid adjustments, and thanks to our extensive design department, we can work flexibly with common file formats.

From sketch to product

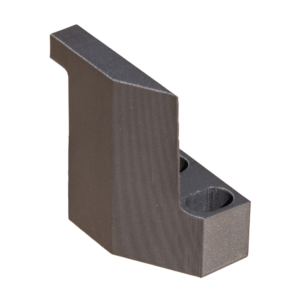

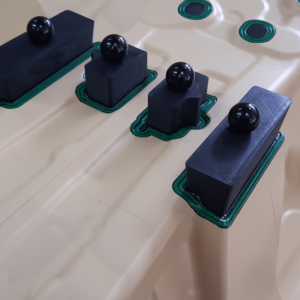

Even without a print-ready file, a sketch or an existing component is all we need to create a product. In plastic 3D printing, we process a variety of materials and offer solutions for a wide range of industries and challenges.

- Plastic 3D printing:

– Component dimensions: approx. 250 mm x 355 mm x 250 mm - Metal 3D printing:

– Component dimensions: approx. 1,200 mm x 2,000 mm x 1,000 mm