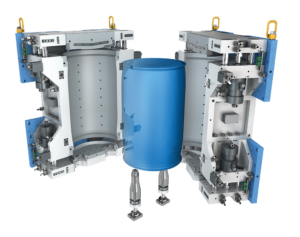

Blow molds

Meissner - Your partner for blow molding

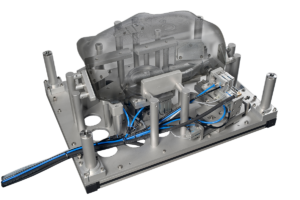

Meissner is your expert for the production of blow-molded plastic hollow parts. Our mold making department produces blow molds for all known manufacturing processes. Using state-of-the-art technologies such as simulation technology and 3D printing processes as well as simultaneous high-speed milling in 5 axes, we quickly implement our customers' wishes. Thanks to our many years of know-how, we can also support you in the implementation of your design ideas. Our continuous investment in modern technology and a large supplier network makes us flexible and independent.

The employee – the greatest asset

Despite state-of-the-art equipment, our employees are the central element for quality and success in blow mold construction. All employees have qualified vocational training and extensive experience.

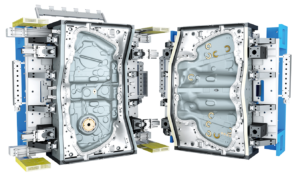

Functionality and precision for the highest possible added value

Our tools not only impress with their functionality and precision, but also with their reliability and durability. Meissner tools ensure the highest possible added value in our customers’ production.

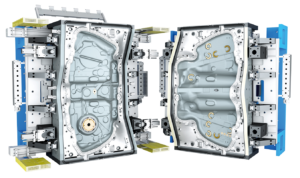

Prototype and series molds

- Fuel tanks

- Filler pipes

- Urea tanks

- Air ducts

- Drums and canisters

- Underground tanks up to 10,000 liters

- IBC and water tanks

- Rotational molds

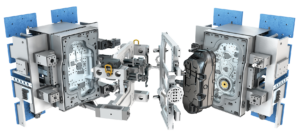

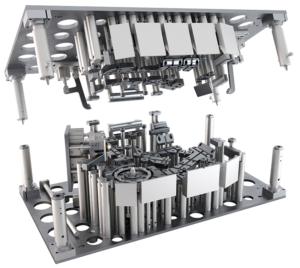

Systems and devices

- Post-cooling devices

- Cooling basins (single and double stations)

- Heating stations (e.g. bottom heating station for melting / preheating components)

- Bell frames with trimming

- Slug punches

- Post-cooling molds

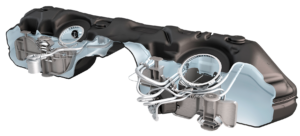

Automation technology

- Basements

- Robot grippers

- Handling devices

- End of Arm Tools

- Removal grippers

- Insertion devices for components

- Handling tools for trimming and cutting

Planning and control

- E-plan and fluid plan

- Robot programming

- Sequence and program planning

Quality improvement

- Testing of mold functions via production-related sequence plans with PLC S7

- Control system

- Endurance tests

- Robot acceptance tests

Out team of experts

Please do not hesitate to contact us!