Innovative solutions for plastic and metal components

Meissner AG is your system partner for

customized solutions in

additive manufacturing.

The advantages of additive manufacturing at Meissner:

- Maximum flexibility: Large build volumes and high build rates for prototypes, small batches, and complex series components.

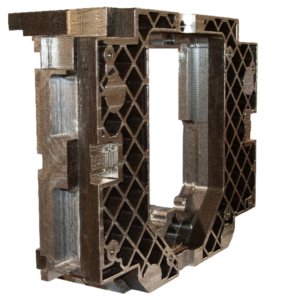

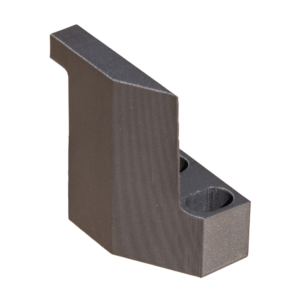

- Complex geometries: Realization of components and tools that would be impossible or very difficult to manufacture using conventional methods – including close-contour cooling, free-form surfaces, and integrated functional areas.

- Fast implementation: Reduced development and production times through direct manufacturing from 3D CAD data, without additional tools.

- Sustainability & efficiency: Lower material consumption, less waste, and resource-saving production, ideal for economical small series and sustainable solutions.

- Increased added value: Longer tool life, shorter cycle times, and optimized material utilization for maximum productivity in your manufacturing processes.

Powerful technologies, experienced team

You can rely on our experienced team of toolmaking, mold making, and additive manufacturing specialists, as well as development engineers. We support you from consultation and development through to production, post-processing, and integration of your additive manufacturing solutions—always with a focus on maximum precision, quality, and efficiency.

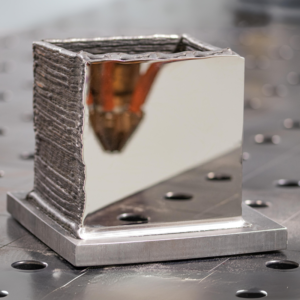

Additive manufacturing in toolmaking – Meissner sets standards

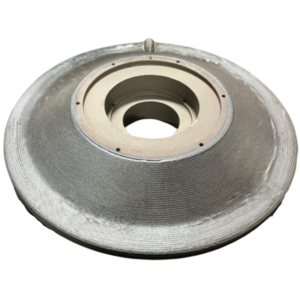

With our specially developed metal 3D printing system, we offer new dimensions in additive manufacturing for toolmaking, plant engineering, and numerous industrial applications. Thanks to generous build space dimensions (up to 1,200 mm x 2,000 mm x 1,000 mm) and an impressive processing speed of up to 7 kg of material per hour, we can also manufacture large-format components quickly, precisely, and efficiently.

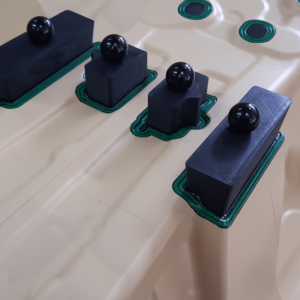

Additive manufacturing is becoming increasingly important, particularly in the automotive industry. It offers potential for lightweight construction, customized component design, and the automation of design and manufacturing processes. For example, tools, handling aids, and fixtures can be manufactured efficiently and economically. Additive manufacturing also contributes to sustainable production by enabling material savings and the reusability of components.

The advantages of modern additive manufacturing

at Meissner at a glance

Resource-efficient and sustainable

Our innovative technology enables economical and environmentally friendly production—ideal for highly stressed functional parts in prototype construction for foundries or tool manufacturing for aluminum and iron foundries.

Cost efficiency

and flexibility

A significant reduction in material usage and rework lowers costs. The rapid implementation of individual parts and small series gives you a real competitive advantage.

Innovative material combinations

Even combinations that were previously considered technically impossible—such as protecting cast material with stainless steel against corrosion or applying special wear-resistant coatings—can now be easily achieved using our additive manufacturing process.

Customized solutions for your industry

Whether medical technology, automation solutions for industry, or sophisticated precision tools: our additive manufacturing enables innovative tools and components that are individually tailored to your requirements.

Success through innovation – Our references in

additive manufacturing

For years, Meissner has been impressing renowned customers with high-quality solutions in the additive manufacturing of plastic and metal components. The following references show how we use state-of-the-art metal 3D printing technology, large build space, and flexible manufacturing capacities to produce customized components for a wide range of industries.

Our team of experts and services for additive manufacturing

Do you have any questions about our innovative solutions in additive manufacturing of plastic and metal components? Our experienced team of specialists in toolmaking, mold making, and 3D metal printing technology is always available to provide you with expert advice.

Contact us now to discuss individual projects or learn more about our resource-saving and flexible manufacturing processes. We look forward to hearing from you!