Your experts for customized mold making and state-of-the-art blow molding technologies

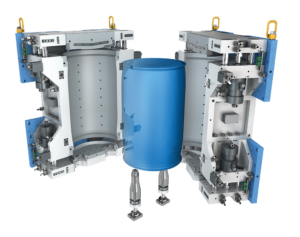

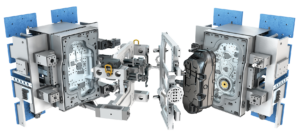

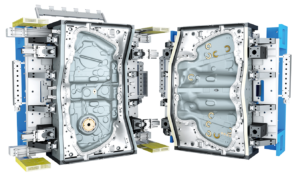

Meissner is your expert partner for the manufacture of blow molds and high-precision mold making for blown plastic hollow bodies. We produce customized blow molds for all common production processes—from development to series production.

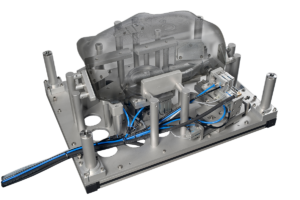

Our experts rely on state-of-the-art technologies such as simulation technology, 3D printing (additive manufacturing), and simultaneous high-speed milling in 5 axes. This enables us to guarantee the highest quality, flexibility, and short delivery times – for your individual requirements in plastics processing and plant engineering.

Through continuous investment in innovative manufacturing methods, a broad supplier network, and comprehensive quality control, Meissner AG remains flexible, independent, and future-proof – from prototype construction to series production.

Precision and innovation in blow molding for prototypes and series production

The advantages of blow mold construction at Meissner AG

- High precision and repeatability: Modern blow molds are manufactured using advanced CNC and metalworking technologies, ensuring exact dimensional accuracy, tight tolerances, and consistent product quality.

- Customized solutions for complex requirements: Thanks to our many years of experience, we can optimally implement customer-specific requirements – even for unusual geometries or demanding applications such as complex rotational molds.

- Time and cost savings in series production: Blow molds enable economical production even for large quantities, while innovative tool systems simplify maintenance and minimize downtime.

- Wide range of materials and industry expertise: These tools are designed for a wide variety of plastics and material properties and can therefore be used in a wide range of industries (e.g., automotive, logistics, agriculture).

- Size flexibility: From small prototypes to large-volume containers with a capacity of several thousand liters, molds can be individually dimensioned according to requirements.

Our qualified blow molding specialists – your key to success

At Meissner, our highly qualified employees in blow mold construction and mold making are at the heart of our success. Despite state-of-the-art manufacturing technologies and innovative production processes, the experience and expertise of our team remain the decisive factor for maximum quality, reliability, and efficiency.

All employees have sound vocational training and years of experience in toolmaking, mold making, blow mold manufacturing, and additive manufacturing. With their know-how, they ensure that every blow mold and every precision tool meets the most demanding requirements of plastics processing and plant engineering. Thanks to continuous training and further education, our specialists always remain at the cutting edge of technology and consistently drive innovation in blow mold construction—for sustainable corporate success and the best results for our customers.

Precision tools for maximum added value in industrial manufacturing

Our precision tools combine first-class functionality with high precision, outstanding reliability, and long service life. With state-of-the-art manufacturing technology and comprehensive expertise in toolmaking, Meissner ensures that your production remains economical, efficient, and sustainable.

Thanks to our holistic approach, innovative solutions, and a qualified team, Meissner tools ensure maximum added value in our customers’ manufacturing processes—from prototype construction to series production.

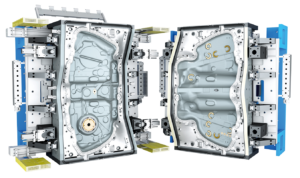

Prototype and series molds

- Fuel tanks

- Filler pipes

- Urea tanks

- Air ducts

- Drums and canisters

- Underground tanks up to 10,000 liters

- IBC and water tanks

- Rotational molds

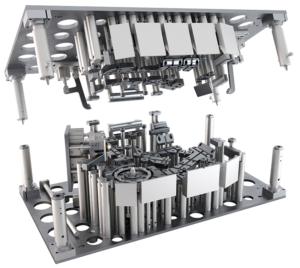

Systems and devices

- Post-cooling devices

- Cooling basins (single and double stations)

- Heating stations (e.g. bottom heating station for melting / preheating components)

- Bell frames with trimming

- Slug punches

- Post-cooling molds

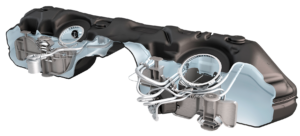

Automation technology

- Basements

- Robot grippers

- Handling devices

- End of Arm Tools

- Removal grippers

- Insertion devices for components

- Handling tools for trimming and cutting

Planning and control

- E-plan and fluid plan

- Robot programming

- Sequence and program planning

Quality improvement

- Testing of mold functions via production-related sequence plans with PLC S7

- Control system

- Endurance tests

- Robot acceptance tests

Trusted by renowned customers – Our successful blow molding projects

We are proud to support numerous renowned companies from a wide range of industries with high-quality blow molds and innovative manufacturing solutions. The following references reflect our commitment to precision, quality, and reliability.

Discover our strong partnerships and see for yourself the capabilities of Meissner as your experienced partner in mold making.

Our team of experts – your point of contact for all questions relating to blow molding

Our dedicated employees and contact persons are at your side with their experience, expertise, and personal commitment. If you have any questions, need advice, or have individual concerns, you will find the direct contact details for the relevant colleagues here—for fast and reliable support for your project.